3 Phase AC Industrial Electric Motors

Product Introduction

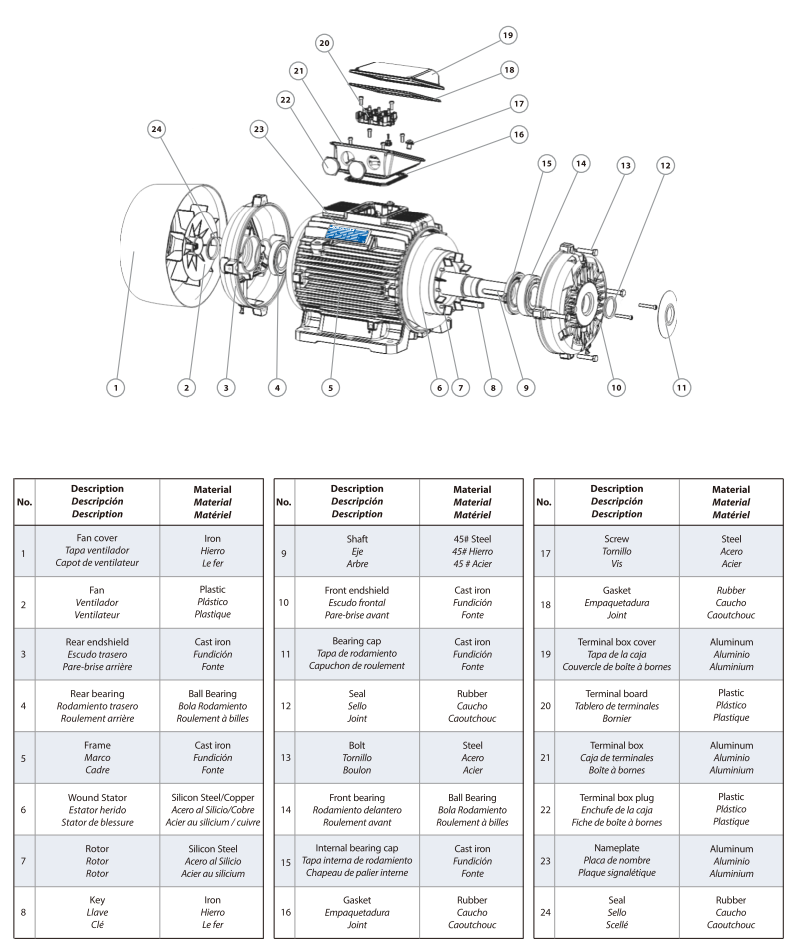

Purity YE3 industrial electric motors feature an enlarged stator and rotor design, ensuring sufficient energy efficiency across a wide range of operating conditions. This optimized design allows for high torque generation and stable operation, reducing the risk of overheating and improving overall system reliability.

High-quality 470-grade silicon steel sheets are used in the stator and rotor cores, effectively lowering iron losses during operation. This improves efficiency and reduces temperature rise, which helps maintain optimal performance even under continuous or heavy-load operation.

Additionally, 3 phase ac electric motors incorporate an increased quantity of copper windings. This reduces copper losses and lowers the motor’s operating temperature, contributing to longer service life and more reliable operation. Purity YE3 3 phase ac electric motor’s enhanced aluminum end rings also minimize aluminum losses, further improving efficiency and energy savings.

Combined, these design features make the Purity YE3 industrial electric motors highly energy-efficient, durable, and capable of sustaining high performance under demanding industrial conditions. Its robust construction and optimized materials ensure reliable operation, lower energy costs, and reduced maintenance requirements.

Purity is one of manufacturing electric motor companies in China, having exported industrial electric motors to electric motor suppliers around the world. If you are looking for industrial electric motors, welcome to inquiry!