In today’s industrial, residential, and agricultural systems, pipeline centrifugal pumps play a crucial role in ensuring reliable and efficient fluid transportation. These pumps are engineered to increase fluid pressure and maintain smooth flow through pipeline systems, offering a compact, energy-saving, and cost-effective solution for various applications.

What is a Pipeline Centrifugal Pump?

A pipeline centrifugal pump—sometimes referred to as a pipeline/horizontal centrifugal pump—is a type of pump that is installed directly in a piping system. It uses centrifugal force to transport liquids by converting rotational energy from a motor into hydrodynamic energy. These pumps are widely used for handling clean water, wastewater, and even certain chemical fluids in industries such as HVAC, water supply, fire protection, and manufacturing.

The term “hot sale pipeline centrifugal pump” often indicates pumps with superior performance, wide market demand, and competitive pricing, ideal for buyers seeking reliable and durable solutions.

How Does a Pipeline Centrifugal Pump Work?

The operating principle of a pipeline centrifugal pump is based on fluid dynamics, particularly Bernoulli’s equation and conservation of energy. Here’s a simplified breakdown of its operation:

1.Start-Up Phase: The electric motor powers the pump’s impeller—a rotating component with curved blades.

2.Suction Phase: As the impeller spins, it creates a low-pressure zone at the pump inlet, drawing fluid into the pump, similar to how a straw draws liquid when you suck on it.

3.Energy Conversion: The rotating impeller imparts velocity to the fluid, increasing its kinetic energy. As the fluid moves along the impeller blades, it gains both speed and pressure.

4.Discharge Phase: The fluid exits the impeller and enters the volute casing or diffuser, where kinetic energy is converted into pressure energy. The pressure rise enables the fluid to be pushed through the connected pipeline system.

5.Continuous Operation: As long as the pump is running, this cycle repeats, maintaining a continuous flow of liquid.

This efficient energy transformation makes the centrifugal design ideal for continuous-duty applications.

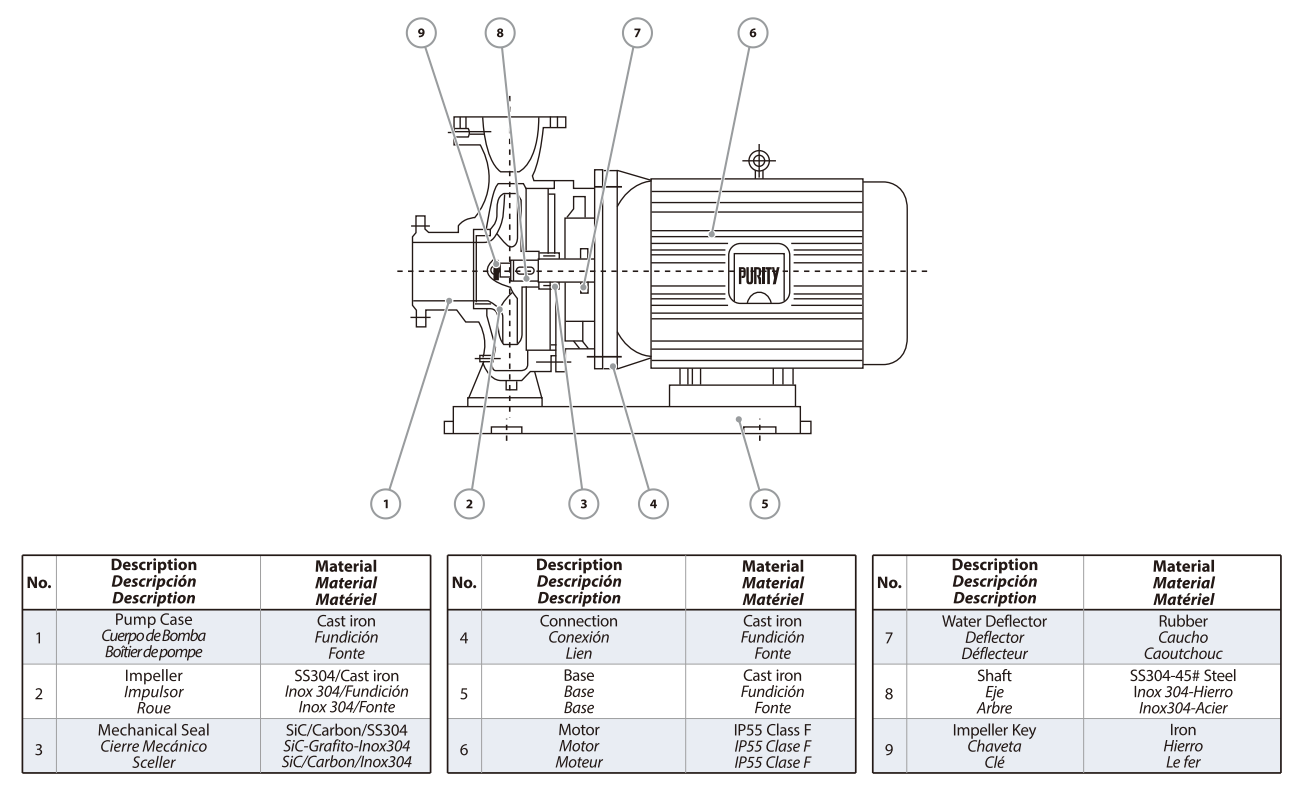

Figure | Internal Parts of Pipeline Pump

Advantages of Pipeline Centrifugal Pumps

Whether it’s a hot sale pipeline pump centrifugal pump for commercial use or a compact unit for residential systems, pipeline centrifugal pumps come with numerous benefits:

1.High Efficiency: Designed for low friction and optimal hydraulic performance, they offer high flow rates with minimal power consumption.

2.Space-Saving Design: Their inline configuration allows direct installation on pipelines, minimizing footprint and reducing installation costs.

3.Easy Maintenance: Many models allow for motor and impeller servicing without removing the entire pump from the pipeline.

4.Versatile Fluid Handling: Suitable for various media—clean water, sewage, hot water, or even corrosive chemicals depending on materials used.

5.Smooth Operation: With balanced impellers and precision engineering, they run quietly with low vibration, enhancing system stability.

Why Choose Purity’s Pipeline Centrifugal Pumps?

Purity’s pipeline centrifugal pump series stands out due to its quality construction, efficient performance, and user-friendly design:

1.Compact & Stable: The pump features a compact structure with its center of gravity aligned to the pump base, improving operational stability and reducing wear.

2.Motor-Pump Coaxial Design: This integration simplifies structure and reduces transmission loss. The impeller is dynamically balanced, resulting in low noise and minimal vibration.

3.Easy to Service: Maintenance is hassle-free. You can remove the motor and internal components without disassembling the pipeline.

4.Certified Quality: Our pipeline pumps are CE and ISO certified, ensuring compliance with international standards.

5.Global Reliability: With over 15 years of experience in production and sales, Purity offers proven solutions and is actively seeking global distributors for its hot sale pipeline centrifugal pump product line.

Figure | Purity Pipeline Pump PG Series

Applications Across Industries

Pipeline centrifugal pumps are essential in:

1.Municipal Water Supply: Providing stable pressure for distribution networks.

2.HVAC Systems: Circulating hot or chilled water in buildings.

3.Fire Protection: As part of pressurized firefighting systems.

4.Irrigation: Delivering water efficiently in agricultural fields.

5.Industrial Plants: Transferring process liquids, cooling fluids, or chemical mixtures.

No matter the environment, these pumps offer the pressure, flow rate, and durability needed for continuous operation.

Figure | Purity Pipeline Pump Project Application Diagram

Final Thoughts

Understanding how a pipeline/horizontal centrifugal pump works helps users make informed decisions on pump selection, operation, and maintenance. As fluid transportation demands grow, the need for reliable and energy-efficient pumps becomes even more important.

Purity’s pipeline centrifugal pumps offer a powerful combination of high performance, minimal maintenance, and international certification. If you’re searching for a hot sale pipeline centrifugal pump that delivers lasting value, explore our range and discover how we can support your projects.

We welcome inquiries from distributors and industry partners around the world—contact us today and join the growing network of businesses choosing Purity as their preferred centrifugal pump supplier.

Post time: Jul-31-2025