Centrifugal pumps are among the most widely used machines for fluid transfer, and one of the most efficient types is the centrifugal submersible pump. These pumps are designed to operate fully immersed in liquid, making them ideal for applications such as well water extraction, wastewater disposal, basement drainage, and flood control. Compared with traditional pumps, they provide reliable performance because they push water instead of pulling it, which reduces the risk of cavitation and eliminates the need for external priming.

In this article, we will explain how a centrifugal submersible pump works, its main features, applications, and why high-quality models like the Purity PZWM series stand out. We will also clarify how these pumps relate to self priming centrifugal pump technology, a popular category among users searching for practical and efficient water transfer solutions.

Definition and Function

A centrifugal submersible pump is a pump that operates while fully submerged in liquid. Its main purpose is to lift water or wastewater from a lower level to a higher level. Unlike pumps that rely on suction, a submersible centrifugal pump pushes liquid upward through the impeller and diffuser system. This makes them particularly useful for:

(1)Pumping water from deep wells or reservoirs

(2)Preventing basement backflow or flooding

(3)Handling greywater or lightly polluted water

(4)Emergency drainage in storms or floods

Because the pump body and motor are sealed as one unit, the pump can work directly under water, improving reliability and reducing priming issues.

Working Principle

At the heart of every centrifugal submersible pump is an electric motor that drives the impeller at high speed (around 3,000 rpm). Here’s how the process works:

Rotation – The impeller rotates and sets the incoming water in motion.

Energy Conversion – The water gains kinetic energy, which is then converted into pressure energy by the diffuser blades.

Liquid Transfer – The pressurized water exits through the pump outlet and into the discharge pipe or hose.

Because the pump works fully underwater, it does not require external priming. This is similar to the concept behind a self priming centrifugal water pump, which is designed to remove air from its casing before operation. Both pump types aim to solve the same problem: ensuring continuous and reliable liquid transfer without losing suction.

If you are wondering how does a self priming centrifugal pump work, the principle is comparable. While submersible pumps avoid air problems by being underwater, a self-priming centrifugal pump uses a special casing design to recirculate water and expel air, allowing it to restart without manual priming.

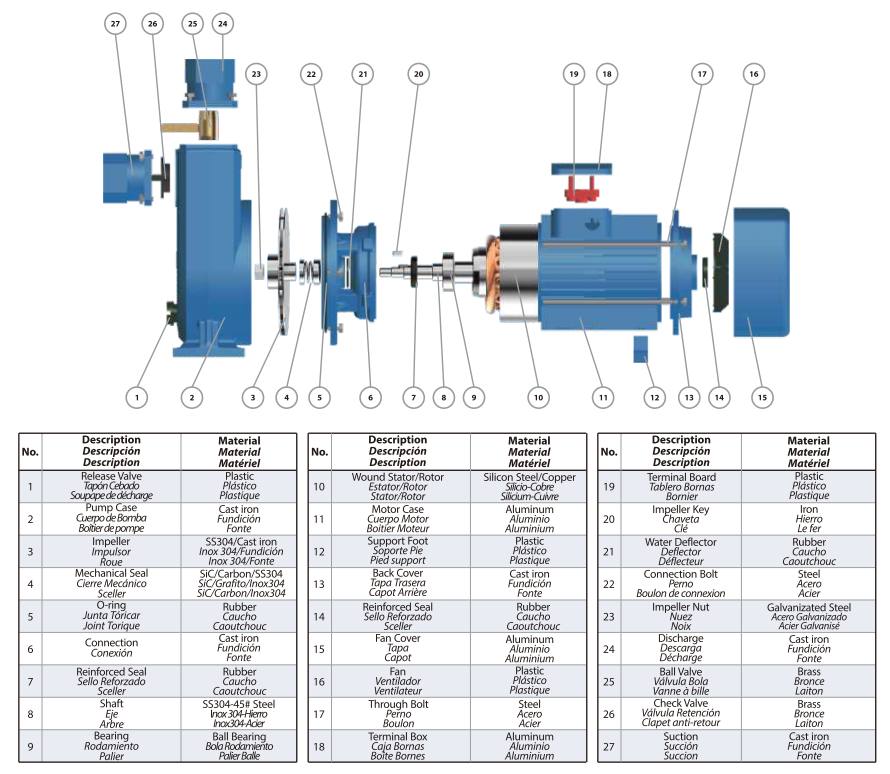

Figure | Purity PXZ Self-priming Centrifugal Pump Components

Structure and Characteristics

Most domestic submersible sewage pumps are equipped with a single impeller, capable of delivering water up to 10 meters in head pressure (about 1 bar). To handle solids, hair, and fibers commonly found in wastewater, the pump body includes a free passage design (for example ≥10 mm), ensuring that particles can pass through without clogging the impeller.

Typical home-use pumps operate at 230V single-phase power, with outputs between 300–800 W. This is sufficient for draining basements, preventing backflow, or emptying storage tanks.

Start and Control

A centrifugal submersible pump is usually controlled automatically by a float switch. As the water level rises, the float activates the motor; once the water drops to the minimum level, the pump switches off again. This automation ensures convenience and energy savings, while protecting the motor from dry running.

Applications

Centrifugal submersible pumps are versatile and suitable for:

Residential use – basement drainage, septic tank emptying, preventing backwater

Emergency use – flood protection, rapid dewatering of basements or construction pits

General transfer – draining swimming pools, ponds, or rainwater barrels

Light industrial use – moving greywater, oils, or other low-viscosity liquids

This versatility makes them a practical choice in both domestic and commercial environments.

Usage Limits and Maintenance

To ensure long service life, users must consider these factors:

(1)Water temperature should not exceed 40°C, since the pump motor relies on water for cooling.

(2)Sand and abrasive particles can wear out the impeller and seals, reducing efficiency and increasing power consumption.

(3)Chemical exposure such as chlorine or acidic water may cause corrosion even in stainless steel housings.

(4)Regular inspection is crucial for permanently installed pumps, since unnoticed failures can cause basement flooding or costly damage.

Purity PXZ Submersible Centrifugal Pump Advantages

As one of the trusted self priming centrifugal pump manufacturers, Purity has developed the PXZ submersible centrifugal pump series with advanced design features:

Durability – Pump shaft made of welded 304 stainless steel, improving anti-rust performance and extending service life.

Efficiency – Equipped with national standard certified energy-saving motors with pure copper coils, offering low temperature rise and high efficiency.

Strong Solid Handling – Wide impeller flow channels provide excellent sewage and particle passing capacity.

Purity has been focusing on centrifugal pump technology for over 15 years, with a 6,000 m² production facility, independent R&D team, and international CE and ISO certifications. Our pumps are exported to more than 130 countries worldwide. We are also actively seeking global distributors who share our commitment to quality and reliability.

Figure | Purity Self-priming Centrifugal Pump PXZ

Conclusion

A centrifugal submersible pump is an efficient, reliable solution for lifting water or wastewater in both residential and industrial environments. With its ability to operate underwater, it eliminates priming problems, prevents cavitation, and ensures stable performance. When comparing technologies like the self priming centrifugal pump, both aim to deliver uninterrupted operation, but the submersible pump achieves this by working directly inside the liquid.

When selecting a pump, consider the type of water, the required head, and the build quality. Investing in a durable, high-performance model like the Purity PXZ submersible centrifugal water pump ensures long-term reliability, reduced maintenance, and peace of mind.

Post time: Sep-10-2025