Fire safety is one of the most critical aspects of building and aircraft design. At the heart of every effective fire protection system lies a sophisticated network of components working together to detect, control, and extinguish fires. In this comprehensive guide, we’ll explore how modern fire fighting systems function, with special focus on key components like fire pumps, vertical fire pumps, jockey pumps, and AC fire pump systems.

The Three Pillars of Fire Protection Systems

Every effective fire fighting system operates on three fundamental principles:

1. Prevention: Using fire-resistant materials and smart design

2. Detection: Early identification of smoke, heat, or flames

3. Suppression: Rapid response to control and extinguish fires

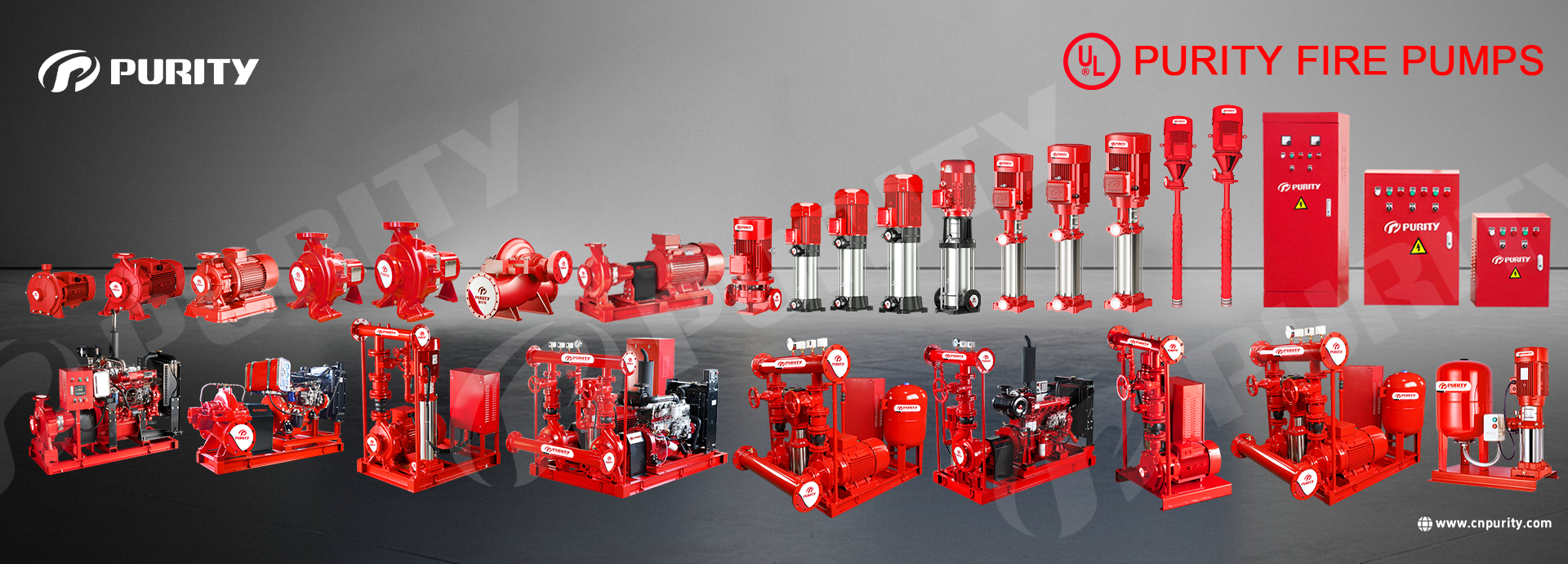

Figure | Purity Fire Pump Full Range

Core Components of a Fire Pump System

1. Fire Pumps: The Heart of the System

Fire pumps serve as the powerhouse of any fire protection system. These specialized pumps:

- Maintain constant water pressure in sprinkler systems and hydrants

- Can be electrically powered (AC fire pump) or diesel-driven for backup

- Are rated by flow capacity (GPM) and pressure (PSI)

- Must meet strict NFPA 20 standards for fire protection

At Purity, our multi-stage vertical fire pumps (PVK series) feature:

✔ Compact, space-saving design

✔ Diaphragm pressure tanks for long-term air retention

✔ Full CCCF certification for guaranteed performance

Figure | Purity PVK Multistage Fire Pump

2. Jockey Pumps: The Pressure Guardians

Jockey pump fire systems play a crucial support role by:

- Maintaining optimal system pressure (typically 100-120 PSI)

- Compensating for minor leaks in the piping network

- Preventing main fire pumps from short-cycling

- Operating intermittently to conserve energy

3. Vertical Turbine Pumps: For Challenging Installations

Fire vertical pump systems offer unique advantages:

- Ideal for limited space applications

- Can draw water from underground tanks or wells

- Multi-stage designs provide high pressure output

- Our PVK series delivers exceptional efficiency in a compact footprint

How the Complete System Works Together

1. Detection Phase

- Smoke/heat sensors identify potential fire

- Alarm signals activate evacuation procedures

2. Activation Phase

- Sprinklers open or firefighters connect hoses to hydrants

- Pressure drop triggers the fire pump system

3. Suppression Phase

- Main fire pumps engage to deliver high-volume water

- Jockey pump maintains baseline pressure

- In aircraft, halon or other agents suppress flames

4. Containment Phase

- Fire-resistant materials prevent spread

- Specialized systems (foam/gas) tackle unique hazards

Why Proper Pump Selection Matters

Choosing the right fire pump system involves considering:

- Water supply: Tank capacity and refill rates

- Building size: Total sprinkler/hydrant demand

- Power reliability: Need for backup diesel pumps

- Space constraints: Vertical vs horizontal configurations

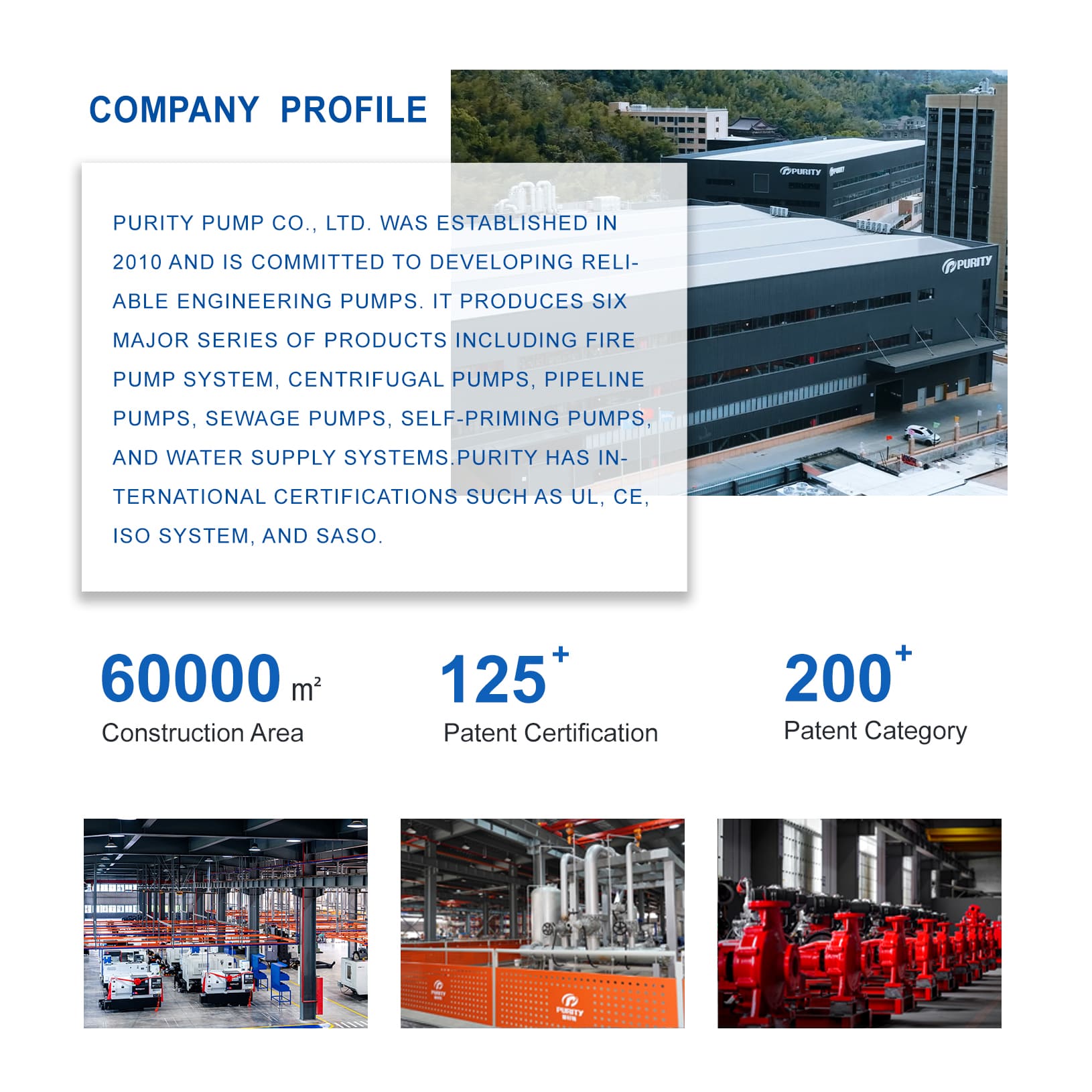

Purity‘s 15 years of expertise in fire pump manufacturing ensures:

→ Energy-efficient designs that reduce operating costs

→ Global certifications for universal compliance

→ Compact solutions for space-limited installations

Figure | Introduction of Purity

Advanced Applications

Modern fire fighting systems now incorporate:

- Smart monitoring: IoT sensors for predictive maintenance

- Hybrid systems: Combining water mist with gas suppression

- Aircraft-specific: Lightweight but extremely reliable pumps

Conclusion: Your First Line of Defense

A properly designed fire pump system doesn’t just protect property—it saves lives. From the jockey pump maintaining daily pressure to the main AC fire pump delivering thousands of gallons per minute during an emergency, each component plays a vital role.

At Purity, we’re proud to manufacture fire fighting equipment trusted in over 120 countries. Our vertical fire pump solutions combine German engineering with global safety standards. We’re currently seeking international distribution partners—contact us today to discuss how we can enhance fire safety in your market.

Post time: Jun-26-2025