Selecting and sizing a fire pump is one of the most critical steps in designing a reliable fire protection system. A properly sized fire fighting booster pump ensures that sprinklers, hydrants, and other fire suppression equipment receive the flow and pressure needed to control or extinguish a fire. On the other hand, a pump that is too small risks system failure, while an oversized pump leads to unnecessary costs, wasted energy, and even potential safety hazards such as pipe damage from excessive pressure. This article explains how to size a fire pump correctly, the main design considerations, and why choosing the right fire fighting pump suppliers is essential.

1. The Importance of Fire Pumps

A fire pump is the heart of the fire protection system. It provides the pressure and flow required for sprinkler systems, standpipes, and outdoor hydrants. Fire pumps are particularly necessary in:

(1) High-rise buildings where municipal water pressure is insufficient.

(2) Industrial plants with large sprinkler systems.

(3)Sites using storage tanks, ponds, or wells as non-pressurized water sources.

Without a correctly sized pump, even the best-designed sprinkler system will fail to deliver water effectively.

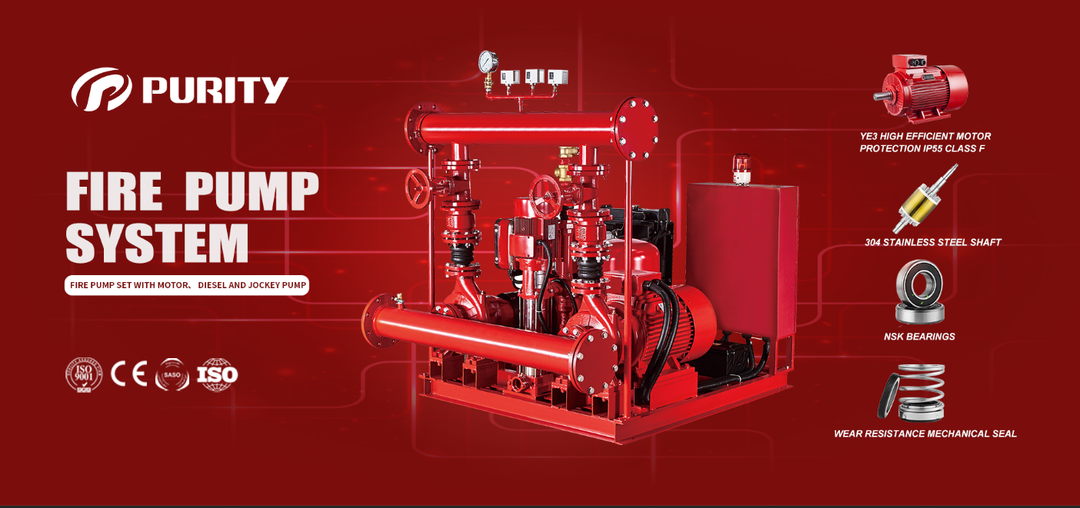

Figure | On-site application of Purity fire fighting pump project

2. Compare Water Supply with System Demand

The first step in sizing a fire booster pump system is to compare the available water supply with the fire protection system’s demand.

(1) If the available water source (city mains, tank, or reservoir) already meets the required flow and pressure, a pump may not be necessary.

(2) If demand exceeds supply, a fire pump must be installed to make up the difference.

A hydrant flow test is commonly performed to establish the water supply curve. The designer then compares this curve with the demand curve of the sprinkler or hydrant system.

3. Calculating System Demand

Fire protection demand is determined by codes such as NFPA 13. The calculation considers:

(1) Sprinkler systems: Water demand for the most remote area, based on hazard classification (light, ordinary, or extra hazard).

(2) Standpipe systems: Flow requirements for hose connections at the most unfavorable location.

(3) Pressure losses: Friction loss in pipes, elevation differences, and other system losses.

By adding these elements, the engineer determines the minimum flow and residual pressure that the fire fighting water pumps for sale must provide.

4. Understanding Fire Pump Performance Curves

Every fire pump has a performance curve showing the relationship between flow and pressure. According to NFPA 20:

(1) At 100% rated flow, the pump must deliver its rated pressure.

(2) At 150% rated flow, the pump must still provide at least 65% of rated pressure.

(3) At shutoff (0% flow), the pump cannot exceed 140% of rated pressure.

This ensures that the pump operates reliably across a range of conditions without overloading the system.

5. Choosing Pump Type and Driver

Different pump configurations are available depending on space, cost, and water source:

(1) Horizontal split-case pumps: High efficiency, long life, suitable for large flow systems.

(2) Vertical turbine pumps: Ideal when water is drawn from tanks, wells, or reservoirs.

(3) Positive displacement pumps: Used for special applications where constant flow is required.

As for drivers:

(1) Electric fire pumps are compact, cost-effective, and easy to maintain where reliable power is available.

(2) Diesel-driven fire pumps are independent of the electrical grid, making them suitable for facilities where power reliability is uncertain.

The choice between electric and diesel depends on system criticality, local regulations, and budget.

Figure | Purity fire pump full range

6. Installation Considerations

Pump installation is not just about hydraulics—it also depends on building layout and maintenance needs:

(1) Horizontal pumps are easier to service but require more floor space.

(2) Vertical pumps save space but can be more expensive to maintain.

Designers should plan pump room space early in the project to avoid costly modifications later.

7. Balancing Safety and Economy

The best fire pump design is one that strikes a balance between safety, code compliance, and cost. An undersized pump puts lives and property at risk, while an oversized one increases capital, energy, and maintenance expenses. Proper sizing ensures “just right” performance—enough pressure and flow to meet NFPA requirements without overspending.

8. Example of Reliable Fire Pump Systems

Among modern solutions, the Purity PEDJ fire fighting pump system demonstrates how advanced fire pump design can support system reliability. Key features include:

(1) A wide range of models to suit various applications.

(2) Integrated diesel engine backup for power outages, with battery start capability.

(3) Safety functions such as overspeed, low oil pressure, and high temperature alarms with automatic shutdown, significantly reducing maintenance costs.

Such innovations highlight why selecting trusted fire fighting pump suppliers matters—reliability in emergencies depends on product quality.

Figure | Purity fire fighting system PEDJ

Conclusion

Sizing a fire pump requires more than choosing a model from a catalog. It demands careful comparison of water supply and system demand, accurate hydraulic calculations, understanding pump curves, and selecting the right pump type and driver. With proper sizing, a fire booster pump system ensures fire protection equipment performs as intended—providing safety, compliance, and peace of mind.

For those looking for reliable fire fighting water pumps for sale, partnering with professional fire fighting pump suppliers is the most effective way to ensure both system safety and cost efficiency.Purity hopes to be your first choice. If you are interested, please contact us immediately.

Post time: Sep-24-2025