A close coupled centrifugal pump is a compact and efficient type of centrifugal pump widely used for transferring water and other liquids with properties similar to clean water. Unlike traditional frame-mounted pumps, a close coupled pump integrates the pump and motor on a single shaft, which eliminates the need for couplings and reduces the overall footprint. This design makes it ideal for applications where space is limited and installation convenience is a priority.

Structure and Design

Close coupled centrifugal pumps are designed to be installed either horizontally or vertically, providing flexibility for various installation requirements. In most designs, the impeller is mounted directly on the motor shaft, allowing for smooth transmission of power and reducing mechanical losses. The compact structure not only saves space but also simplifies alignment during installation.

In close coupled end suction centrifugal pumps, the suction and discharge ports are typically aligned on the same centerline, making it easy to connect to existing piping systems. This feature allows the pump to be installed like a standard valve in a pipeline without complex modifications. The single-shaft design also reduces vibration and ensures stable running, while the mechanical seal prevents leakage and guarantees a clean and safe working environment.

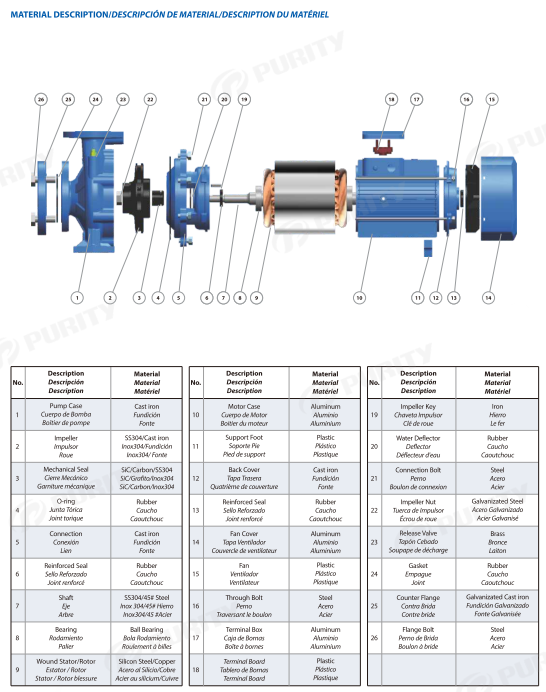

Picture | Purity Close Coupled Centrifugal Pump PSTG Material Description

Advantages of Close Coupled Pumps

The close coupled centrifugal pump offers several key advantages that make it a popular choice for industrial and municipal applications:

(1)Compact and Space-Saving Design – With a smaller footprint and integrated motor and pump assembly, these pumps are ideal for installations where space is limited, such as high-rise building water supply, fire-fighting booster systems, and garden irrigation projects.

(2)Stable Operation – High-quality bearings and dynamically balanced impellers minimize vibration and noise, ensuring smooth and reliable operation even under continuous running conditions.

(3)Easy Installation and Maintenance – Due to the close-coupled design, the pump can be mounted without specialized alignment. Maintenance is simplified because components can be removed without disconnecting the entire pipeline.

(4)Leak-Free Operation – Most close coupled pumps use mechanical seals with durable materials like carbide alloy faces, ensuring long-lasting, leak-free performance.

(5)Versatile Applications – From industrial and municipal water supply to heating systems, hot and cold water circulation, fire-fighting systems, and remote water supply, close coupled centrifugal pumps meet a wide range of requirements.

The Purity PSTG close coupled centrifugal pumps provide additional features that enhance performance and reliability:

(1)Optimized Pump Body Design – The inlet diameter is larger than the outlet, reducing turbulence and minimizing vapor formation, resulting in quieter, smoother operation.

(2) High-Quality Motor Protection – IP55-rated motor protection with F-class winding ensures durability in various environments, including outdoor installations.

(3)Certified and Reliable – PSTG pumps have received CE certification, ensuring compliance with international quality standards.

(4)Wide Range of Models – Available in multiple specifications, the PSTG series can meet different flow, head, and application requirements.

Picture | Purity Close Coupled Centrifugal Pump PSTG

Applications

Close coupled end suction centrifugal pumps are versatile and widely used across industries:

(1)Industrial Water Supply – Efficiently handles clean water for production processes.

(2)Municipal Water Distribution – Supports city water supply and drainage systems.

(3) High-Rise Building Boosters – Ensures consistent water pressure in multi-story buildings.

(4)Fire-Fighting Systems – Reliable booster pumps for emergency applications.

(5)Irrigation and Cooling Systems – Suitable for garden irrigation, HVAC, and circulating water systems.

(6)Chemical, Pharmaceutical, and Food Industries – Compatible with clean liquids and other non-corrosive fluids.

Conclusion

A close coupled centrifugal pump is an ideal choice for applications requiring a compact, efficient, and reliable solution. With its small footprint, easy installation, stable operation, and minimal maintenance requirements, it is suitable for medium-power, low- to medium-head applications.

Purity, a professional industrial pump manufacturer with a 60,000-square-meter factory and over 15 years of experience, offers a wide range of close coupled centrifugal pumps. Their products are exported to more than 130 countries, and the company is actively seeking global distributors. With the PST series, you get high-quality, durable, and certified pumps suitable for a variety of industrial, municipal, and commercial applications.

Whether you are looking for close coupled centrifugal pumps, close coupled end suction centrifugal pumps, or other types of centrifugal water pumps, Purity provides reliable solutions tailored to your needs.

Post time: Jan-12-2026