A fire pump is one of the most critical components in modern fire protection systems. In commercial and industrial buildings, fire pumps play a vital role in ensuring that adequate water pressure and flow are always available for the sprinkler and hydrant systems — especially during emergencies or when the local water supply cannot meet the system’s demands.

The Role of Fire Pumps in Fire Protection Systems

In many large buildings, municipal water pressure alone is insufficient to reach the farthest or highest sprinkler heads. Fire pump systems solve this problem by boosting water pressure and ensuring that the fire sprinkler system can distribute water effectively throughout the entire facility. In essence, a sprinkler fire pump acts as the heart of a fire protection system — maintaining the constant water pressure necessary for fire suppression and safety.

When a fire breaks out, heat-activated sprinkler heads open, causing a drop in system pressure. This pressure drop triggers the fire pump controller, which automatically starts the pump. The fire pump then draws water from a storage tank or municipal line, pressurizes it, and delivers it through the sprinkler and standpipe systems to suppress the fire efficiently.

Types of Fire Pumps

Modern fire pump systems generally include three main types of pumps, each designed to serve different installation needs and operational conditions:

1.Electric Motor-Driven Fire Pumps

These pumps are powered by electric motors and are ideal for buildings with a stable electrical supply. They are quiet, efficient, and require less maintenance. Electric pumps are commonly used in commercial offices, hotels, and shopping centers.

2.Diesel Engine-Driven Fire Pumps

In locations where electricity may be unreliable, diesel fire pumps are preferred. Driven by internal combustion engines, they can operate independently during power outages or emergencies, making them suitable for factories, high-rise buildings, and critical facilities such as hospitals and data centers.

3.Jockey Pumps (Pressure Maintenance Pumps)

A jockey pump is a small auxiliary pump that maintains constant system pressure during normal operation. It prevents the main sprinkler system fire pump from frequently starting due to minor pressure fluctuations caused by small leaks or thermal expansion.

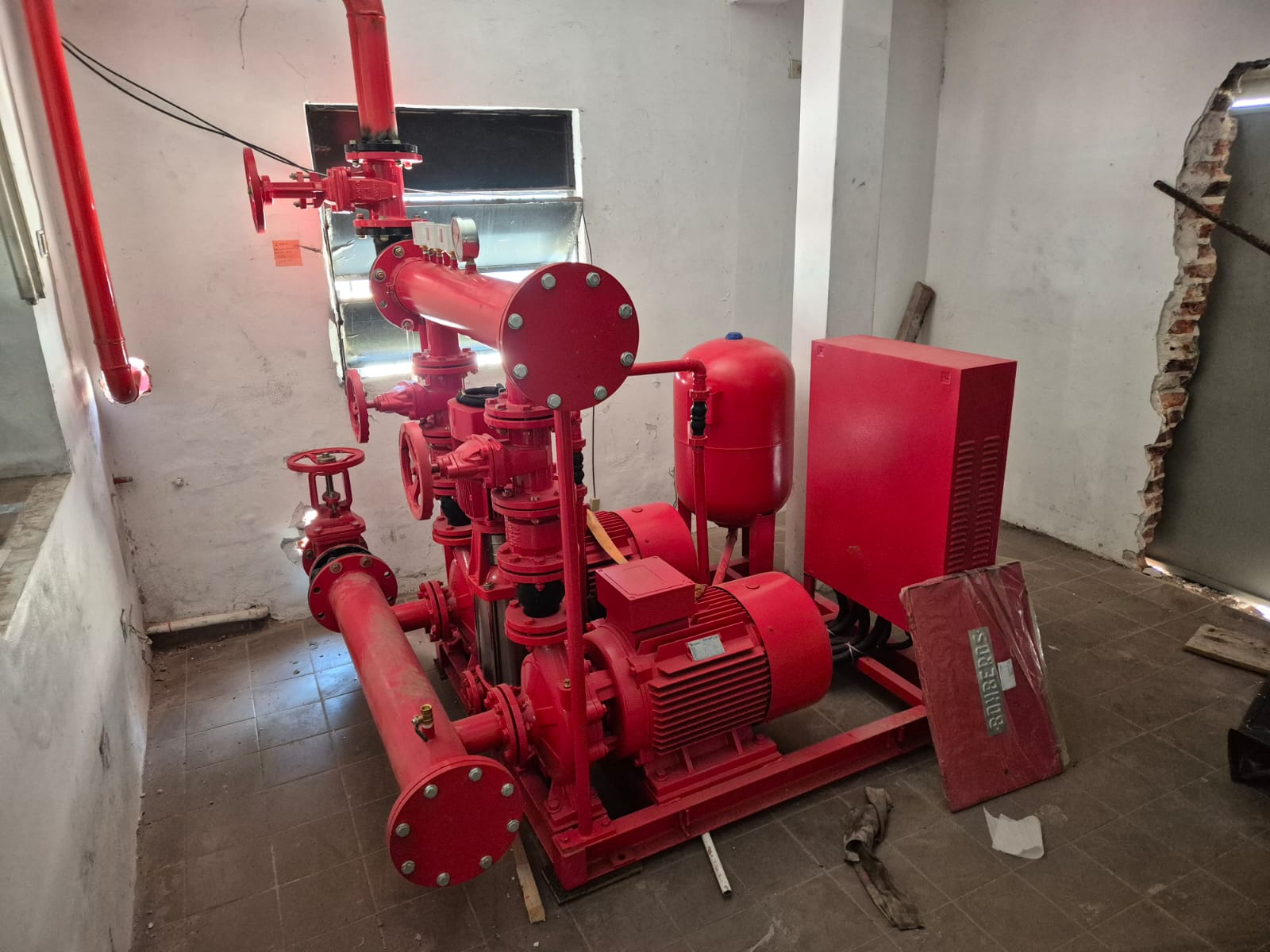

Picture | Purity Fire Pump Full Series

Main Components of a Fire Pump System

A complete fire pump system consists of several key components that work together to ensure consistent and reliable operation:

1.Pump Assembly: The core component that increases water pressure and flow.

2.Driver (Electric Motor or Diesel Engine): The power source that drives the pump.

3.Controller: Automatically starts and stops the pump based on system pressure changes.

4.Jockey Pump: Maintains normal system pressure and reduces wear on the main pump.

5.Relief Valve: Protects the system by releasing excess pressure.

6.Check and Isolation Valves: Ensure correct water flow direction and allow for safe maintenance.

Each element of the system is designed for precision, safety, and compliance with international standards such as NFPA 20, which governs the installation of stationary fire pumps for fire protection.

Why Fire Pumps Are Essential for Large Buildings

In large or high-rise commercial structures, water must travel through long pipelines and rise to upper floors, leading to significant pressure loss. Without a fire pump, the water may not reach distant sprinkler heads with enough force to extinguish flames effectively.

Additionally, facilities like warehouses, manufacturing plants, and data centers often require large volumes of water for fire suppression due to flammable materials or sensitive equipment. In such cases, fire pumps draw water from on-site tanks and boost the flow to meet these high-capacity demands.

By ensuring a consistent and powerful water supply, fire pump systems safeguard not only buildings but also lives and valuable assets.

Picture | Application diagram of Purity fire pump

Fire Code Compliance and System Reliability

Compliance with fire protection standards is another key reason for installing fire pumps. Local fire codes and international regulations often mandate the use of pumps in buildings that exceed certain height or size thresholds.

Proper installation and maintenance of sprinkler system fire pumps guarantee that the system operates as intended during an emergency. They also help building owners meet the requirements of fire authorities, insurers, and safety audits.

Choosing the Right Fire Pump Manufacturer

When selecting a fire pump manufacturer, reliability, certification, and technical expertise are crucial. Purity stands out as a trusted industrial pump manufacturer with over 15 years of production and engineering experience.

Purity offers a wide range of fire pumps, including multistage pumps, end suction pumps, and vertical inline pumps, as well as complete diesel engine-driven fire pump units. The company’s product line is designed to meet diverse client needs, and several models are certified to international UL standards.

Beyond pump manufacturing, Purity also provides complete fire pump systems — integrating pump units, diesel engines, controllers, and accessories — ensuring one-stop solutions for building fire safety.

Conclusion

Whether driven by an electric motor or a diesel engine, a sprinkler system fire pump is the backbone of a building’s fire protection system. It bridges the gap between limited municipal water pressure and the high-pressure demands of modern fire suppression systems.

With advanced design, strong performance, and reliable compliance with NFPA 20 standards, fire pumps ensure that water flows where and when it is needed most — protecting people, property, and peace of mind.

If you are looking for dependable fire pump manufacturers, Purity offers proven expertise, global certification, and comprehensive support. As we expand worldwide, we welcome partners and distributors to join us in delivering safer and smarter fire protection solutions.

Post time: Nov-13-2025