A centrifugal pump is one of the most widely used fluid-handling devices in municipal, industrial, and agricultural systems. Known for its simplicity, efficiency, and ability to handle a wide range of fluids, this pump operates on a fundamental principle involving centrifugal force. This article provides a comprehensive overview of how centrifugal pumps work, with a focus on pipeline centrifugal pump systems, common applications, and modern product innovations like the hot sale pipeline centrifugal pump series.

1. Centrifugal Pump Definition

A centrifugal pump is a mechanical device that moves fluid using the transfer of rotational energy from one or more driven impellers. As the impeller spins, it creates centrifugal force, which accelerates the liquid outward from the pump center toward the casing, thereby increasing its velocity and pressure. This process enables centrifugal water pumps to deliver a continuous and steady flow, ideal for both low and high-capacity fluid transfer.

2. Core Components and Structure

To understand the operation of a centrifugal pump, it’s important to first understand its key components:

(1) Impeller: The rotating part that imparts kinetic energy to the liquid.

(2) Pump Shaft: Connects the impeller to the driving motor.

(3)Casing: Encases the impeller and directs fluid flow.

(4)Seal and Bearings: Prevent leakage and support rotational movement.

(5)Suction and Discharge Ports: Allow fluid to enter and exit the pump.

In pipeline centrifugal pumps, these components are often integrated into a compact, inline design where the pump’s inlet and outlet are aligned, making installation and maintenance more convenient.

3. How a Centrifugal Pump Works

The operational process of a centrifugal pump involves the following steps:

(1)Priming: The pump casing is filled with liquid to eliminate air pockets, which allows for efficient suction.

(2)Suction Phase: When the pump starts, the impeller begins to rotate, creating a low-pressure zone at the center (eye) of the impeller.

(3)Acceleration: Fluid enters the impeller eye and is thrown outward by centrifugal force.

(4)Conversion of Energy: The kinetic energy is converted into pressure energy as the fluid moves through the volute or diffuser in the casing.

(5)Discharge: The high-pressure fluid exits through the discharge port and is sent to the required system.

This process is continuous, enabling centrifugal water pumps to maintain steady flow without pulsation, unlike positive displacement pumps.

4. Types of Centrifugal Pumps and Applications

There are many types of centrifugal pumps, each tailored for specific uses:

|

Type |

Key Feature |

Application |

|

Single-Stage Pump |

Simple design, low head |

Building water supply, cooling |

|

Multistage Pump |

High head, multiple impellers |

Boiler feed, high-rise buildings |

|

Axial Flow Pump |

High flow, low pressure |

Irrigation, flood control |

|

Mixed Flow Pump |

Mid-range flow and head |

Agriculture, municipal systems |

|

Self-Priming Pump |

Easy operation |

Mobile pump stations, drainage |

|

Submersible Pump |

Fully immersed operation |

Sewage, deep wells |

|

Sewage/Trash Pump |

Handles solids |

Construction, wastewater treatment |

One of the most popular categories is the pipeline centrifugal pump, which is widely used in HVAC systems, urban water supply, and industrial circulation due to its inline configuration and compact footprint.

Figure | Purity Centrifugal Pump Full Range

5. Material Selection and Efficiency Factors

The performance and longevity of a centrifugal pump greatly depend on the material used:

(1)Cast Iron: Cost-effective and durable for clean water.

(2)Stainless Steel: Corrosion-resistant, used in food and chemical industries.

(3)Bronze: Ideal for seawater and sanitary applications.

(4)Engineering Plastics: Suitable for corrosive or acidic fluids.

When selecting a centrifugal pump, consider the following:

(1)Medium characteristics (temperature, pH, solids)

(2)Required flow rate and pressure (head)

(3)Environmental conditions and installation space

6. Advantages and Limitations

Centrifugal pumps offer numerous advantages:

Pros:

(1)Simple and compact structure

(2)High flow rate with continuous delivery

(3)Low maintenance and operating costs

(4)Quiet and stable performance

Cons:

(1)Limited suction lift; needs priming

(2)Not ideal for high-pressure, low-flow needs

(3)Sensitive to fluid impurities and cavitation

7. Why Choose a Hot Sale Purity Pipeline Centrifugal Pump PG Series?

Modern hot sale pipeline centrifugal pumps like those from Purity Pump stand out due to:

(1)Compact inline design for easy integration into pipe networks

(2)Motor-pump coaxial structure to reduce vibration and noise

(3)Tool-free maintenance with easy access to internal components

(4)CE certification and global quality assurance

The Purity PG series pipeline pump is especially favored in industrial settings for its stability, low noise, and efficient operation. Its design allows users to conduct repairs without dismantling the piping system—a major advantage for urban infrastructure and process industries.

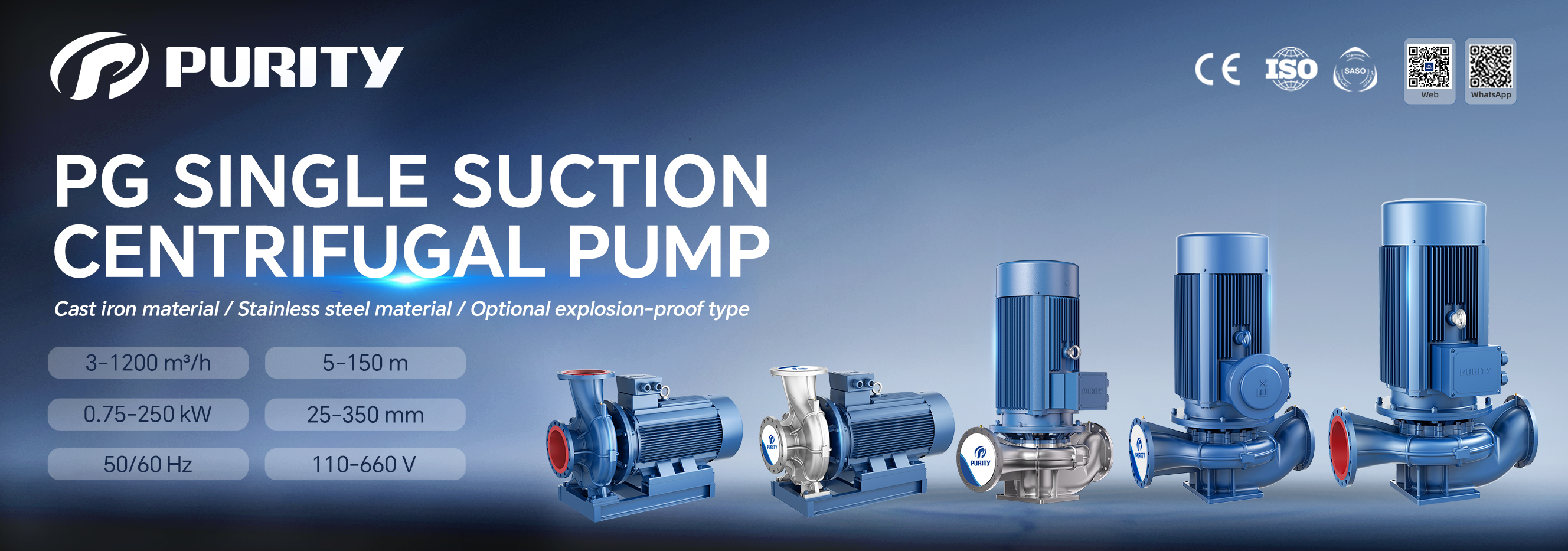

Figure | Purity Centrifugal Pipeline Pump PG Series

8. Conclusion

Understanding the operation process of a centrifugal pump is fundamental to optimizing system design in any fluid handling application. Whether it’s a centrifugal water pump for a residential booster system or a pipeline centrifugal pump for a manufacturing plant, choosing the right pump based on performance needs, installation conditions, and fluid characteristics is key. With decades of innovation and field-proven reliability, products like the Purity PG pipeline pump are redefining standards in pump efficiency and user experience.

If you’re seeking a reliable solution or interested in becoming a distributor, reach out today to learn more about our full line of centrifugal pump solutions.

Post time: Jul-24-2025