AC electric motors are some of the most widely used devices in both residential and industrial settings. From washing machines and ovens to industrial pumps and compressors, these motors provide reliable and efficient mechanical power. Understanding how an AC electric motor works, particularly the AC induction electric motor, can help when troubleshooting, replacing, or selecting motors for various applications.

Parts of an AC Electric Motor

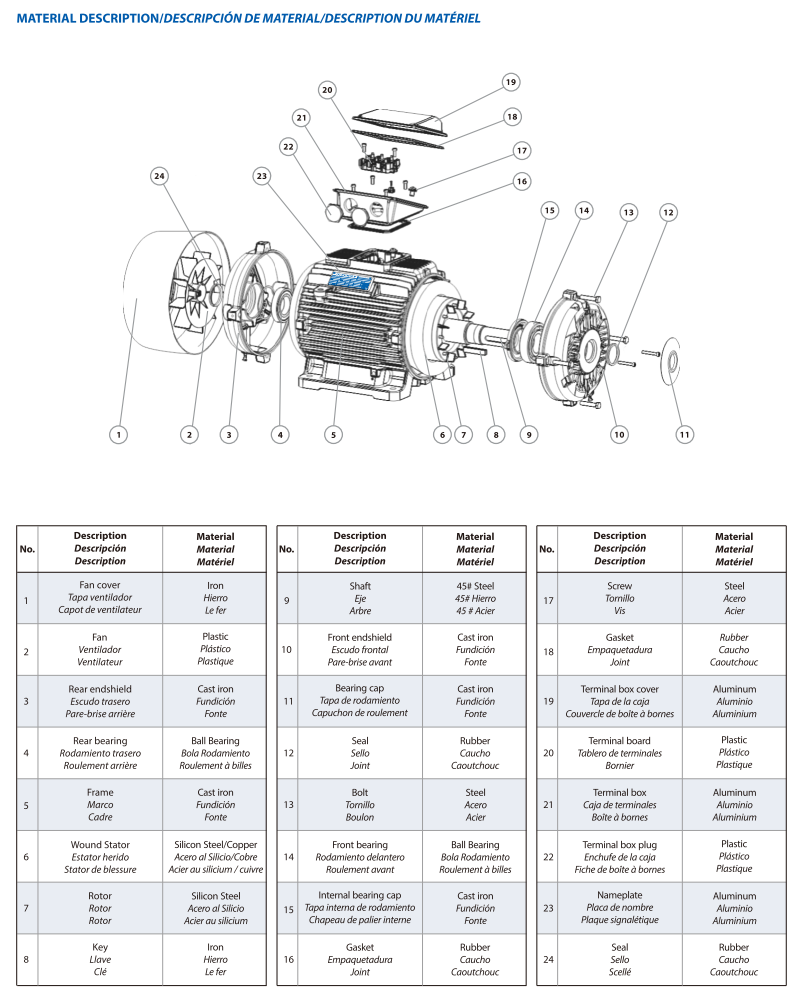

An AC electrical motor is composed of several key components that work together to convert electrical energy into mechanical motion. The enclosure or housing protects the internal components and provides structural support. The connection box allows for wiring the motor to a power source and integrating peripheral control circuits.

Attached to the back of the motor is the fan and cover, which are connected to the shaft. The fan reduces heat buildup, and its efficiency is directly tied to the motor’s speed. The shaft, the only moving part of the motor, is supported by bearings at the front and back, reducing friction and wear while enabling smooth rotation.

Inside the motor, the rotor is typically made of a conductive material, with the squirrel-cage design being the most common type in AC induction electric motors. Surrounding the rotor is the stator, which consists of laminated steel sheets and copper coils insulated with enamel. These coils are arranged in pairs to create three phases, forming a rotating magnetic field when energized.

Figure | Purity YE3 Electric Motor Assembly

How AC Induction Motors Work

AC electric motors operate on the principle of electromagnetic induction, a phenomenon first described by Michael Faraday. When alternating current flows through the stator coils, it generates a rotating magnetic field. This magnetic field passes through the rotor, inducing a current in it. As a result, the rotor produces its own magnetic field, which interacts with the stator’s field, causing the rotor to spin. This rotation transfers mechanical power to the connected load.

AC motors are typically constant-speed devices, with their speed determined by the frequency of the power supply. However, the speed can be easily adjusted using a variable frequency drive (VFD). This feature makes AC electric motors highly versatile for applications that require precise speed control.

Applications of AC Electric Motors

AC electric motors are used across a wide range of applications:

(1)Household appliances: washing machines, ovens, and air conditioners.

(2)Gardening and power tools: lawnmowers, drills, and saws.

(3)Industrial equipment: pumps, fans, compressors, and other machinery that require heavy-duty, continuous operation.

Among AC electric motors, both AC induction electric motors and AC synchronous electric motors are commonly used, with induction motors being the most popular due to their simplicity, reliability, and cost-effectiveness.

Advantages and Limitations

The design of an AC electrical motor is simple, with only one moving part, which results in low maintenance, quiet operation, and long service life. AC motors are also robust and can handle fluctuating loads better than DC motors, making them ideal for industrial and continuous-duty applications.

However, AC motors generally have slightly lower efficiency than DC motors and require additional equipment, such as a VFD, for precise speed control. Despite this, their advantages—reliability, durability, and ease of integration—make them the preferred choice in many scenarios.

Why Choose Purity YE3 AC Electric Motors

Purity, a leading electric motor supplier, has developed the YE3 series AC motors with industrial applications in mind. These motors achieve IP55 protection, with added shaft sleeves and oil seals to prevent water and dust ingress. The reinforced bearing housing reduces vibration, increases bearing lifespan, and lowers operational noise. Shaft locking mechanisms prevent axial movement of the rotor, enhancing stability.

With 15 years of experience in the industrial pump sector and products distributed to over 120 countries, Purity combines proven quality with cutting-edge engineering. Their dedicated R&D team ensures continuous innovation, making Purity a reliable choice for those seeking high-performance AC electrical motors.

Figure | Purity YE3 Electric Motor

Conclusion

Whether you are selecting a motor for home appliances, gardening tools, or industrial machinery, understanding how an AC electric motor works is essential. From the simple yet robust design of the AC induction electric motor to the specialized applications of AC synchronous electric motors, these devices offer reliable, efficient, and long-lasting solutions. Partnering with trusted electric motor suppliers like Purity ensures that you receive high-quality, durable, and globally tested motors suitable for a wide range of applications.

Post time: Aug-15-2025