Do you know? 50% of the country’s annual total power generation is used for pump consumption, but the average working efficiency of the pump is less than 75%, so 15% of the annual total power generation is wasted by the pump. How can the water pump be changed to save energy to reduce energy consumption? Consumption, promote saving and emission reduction?

01 Improve motor efficiency

Develop energy-saving motors, reduce losses by improving stator materials, use high-quality pure copper coils, optimize winding processes, and improve efficiency; do a good job of model selection before sales, which is also of great help to improve the working efficiency of motors.

02 Improve mechanical efficiency

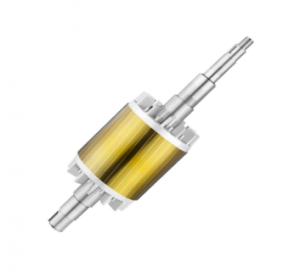

Improve the bearing process and use bearings with good concentricity to reduce bearing loss; do polishing, coating, and wear-resistant treatments for fluid flow parts to reduce damage caused by impacts such as cavitation and friction, and improve pump efficiency It also increases the service life of components. The most important thing is to do a good job in quality control during parts processing and assembly, so that the pump can reach the best operating condition, which can reduce energy consumption and improve work efficiency.

Figure | Stainless steel shaft

03 Improve the smoothness of the runner

When processing and assembling the impeller and the flow part of the blade passage, the rust, scale, burr and flash are polished to reduce the friction and vortex loss between the water and the flow passage wall. It can focus on the key parts that affect the efficiency, such as: the positive guide vane, the inlet part of the impeller, the outlet part of the impeller, etc. It only needs to be polished to see the metallic luster, and at the same time, the scoop deflection of the impeller does not exceed the specified value to reduce the friction loss of the disc.

Figure | pump body

04 Improve volumetric efficiency

The volume loss of the water pump is mainly reflected in the water loss at the seal ring gap. If the joint surface of the sealing ring is inlaid with a steel ring and the “0″ rubber sealing ring is installed, the sealing effect can be significantly improved, and the service life of the same type of sealing ring is greatly improved, which can improve the efficiency of the water pump and reduce the maintenance cost. The effect is remarkable.

Figure | O selection ring

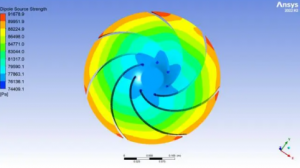

05 Improve hydraulic efficiency

The hydraulic loss of the pump is caused by the impact of the water flow through the channel of the pump and the friction with the flow wall. The main way to improve the hydraulic efficiency of the pump is to select the appropriate working point, improve the anti-cavitation performance and anti-abrasion performance of the pump, and reduce the absolute roughness of the surface of the flow-passing parts. Roughness reduction can be achieved by applying a lubricious coating to the channels of the pump.

Figure | CFD hydraulic simulation

06 Frequency conversion adjustment

The frequency conversion speed regulation operation of the water pump means that the water pump runs under the drive of an adjustable speed motor, and the working point of the water pump device is changed by changing the speed. This greatly expands the effective working range of the water pump, which is a very important and applicable adjustment method in engineering. Transforming a non-speed-regulating motor into a speed-regulating motor, so that the power consumption varies with the load, can save a lot of power.

Figure | Frequency conversion pipeline pump

The above are some ways to save energy in pumps. Like and pay attention to Purity Pump Industry to learn more about pumps.

Post time: Aug-28-2023