Sewage pumps are vital components in numerous settings, including commercial, industrial, maritime, municipal, and wastewater treatment applications. These robust devices are engineered to handle effluents, semi-solids, and small solids, ensuring efficient waste management and fluid transport. Among the various types of sewage pumps, three stand out for their distinct mechanisms and applications: centrifugal pumps, agitator pumps, and grinder pumps. Understanding the characteristics and functionalities of these pumps can help in selecting the appropriate type for specific needs.

1.Centrifugal Pumps

Centrifugal pumps are one of the most commonly used types of sewage pumps. They operate on the principle of centrifugal force, which is generated by a rotating impeller. As the impeller spins, it increases the velocity of the fluid, pushing it outward toward the pump’s discharge outlet. This mechanism allows centrifugal pumps to handle large volumes of fluid efficiently.

(1)Applications and Benefits:

Centrifugal pumps are widely used in scenarios where large quantities of sewage or wastewater need to be moved quickly. They are ideal for municipal sewage systems, industrial wastewater treatment plants, and commercial settings where high flow rates are required. The simplicity of their design means they are relatively easy to maintain and repair. Moreover, centrifugal pumps can handle a variety of fluids, including those with small solid particles, making them versatile for different applications.

(2)Key Features:

- High flow rates and efficient fluid movement.

- Capability to handle fluids with small solid particles.

- Easy maintenance and repair due to simple design.

- Suitable for a wide range of applications, from municipal to industrial.

Picture | purity WQ sewage pump product description

2.Agitator Pumps

Agitator pumps, also known as slurry pumps, are designed to handle fluids containing a high concentration of solids. These pumps incorporate an agitator mechanism that delivers kinetic energy to the surrounding slurry solids, re-suspending them in a fluid state. This capability ensures that solids do not settle and clog the pump, making agitator pumps ideal for handling thick, abrasive slurry.

(1)Applications and Benefits:

Agitator pumps are particularly useful in environments where the fluid to be pumped contains a significant amount of solid materials, such as in mining, construction, and dredging operations. They are also employed in wastewater treatment plants where sludge needs to be moved. The agitator mechanism prevents the accumulation of solids at the pump’s intake, ensuring consistent and reliable operation even in challenging conditions.

(2)Key Features:

- Ability to handle thick, abrasive slurry.

- Prevents clogging by re-suspending solids.

- Ideal for mining, construction, dredging, and sludge handling.

- Reliable performance in challenging environments.

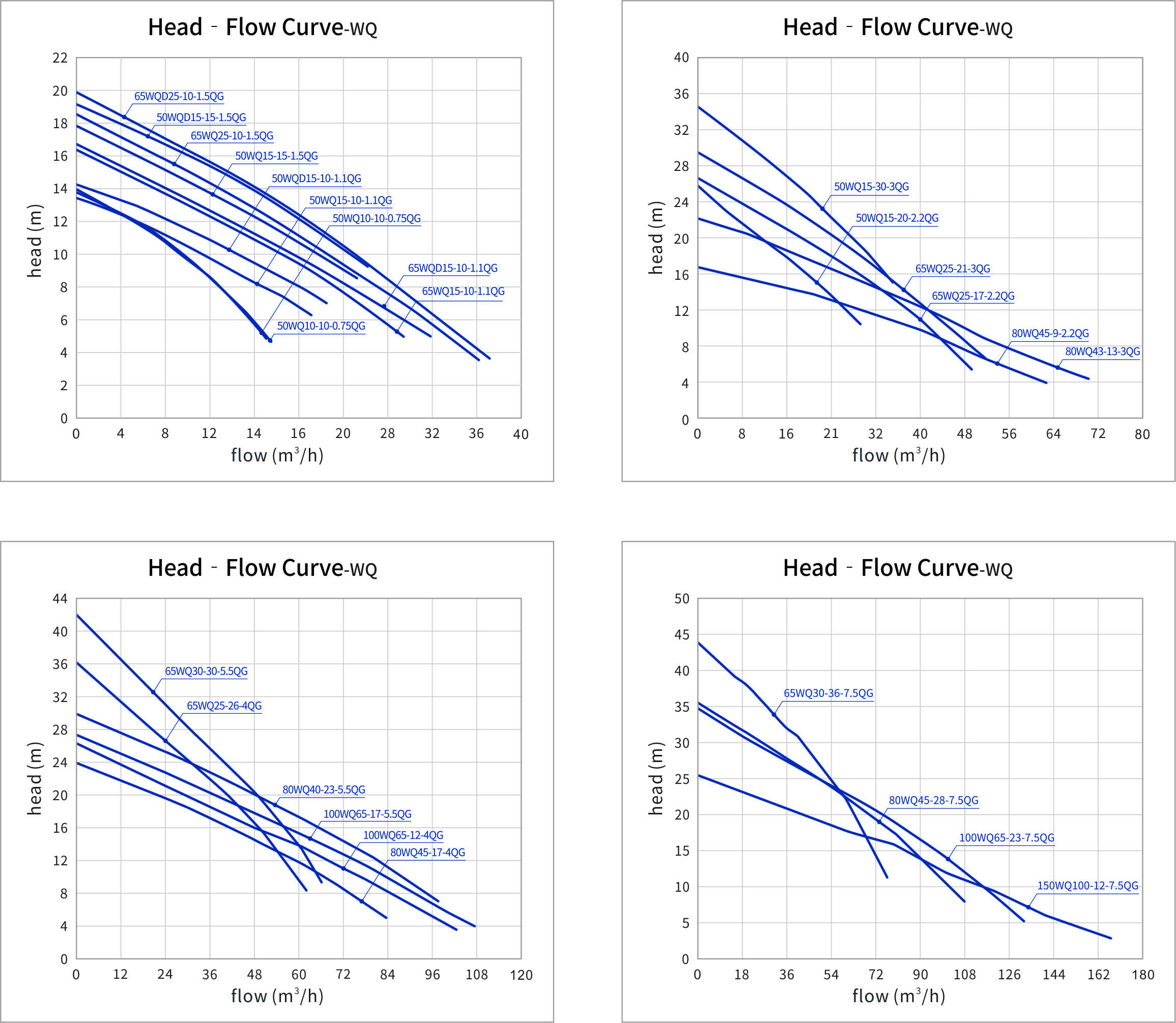

Figure | purity WQ sewage pump curve chart

3.Grinder Pumps

Grinder pumps are designed to handle raw sewage and other solid waste by grinding the solids into a fine slurry. These pumps feature sharp blades that shred the solid waste before it is pumped out. This grinding action ensures that the solids are broken down into a manageable size, preventing clogs and facilitating smooth transport through the sewage system.

(1)Applications and Benefits:

Grinder pumps are essential in residential and commercial settings where raw sewage needs to be transported over long distances or against gravity. They are commonly used in homes with basement bathrooms, restaurants, hotels, and other establishments that generate significant amounts of solid waste. The ability of grinder pumps to efficiently handle larger solids makes them indispensable in preventing blockages and maintaining the integrity of the sewage system.

(2)Key Features:

- Effective grinding mechanism for handling solid waste.

- Prevents clogs by reducing solids to a fine slurry.

- Suitable for residential, commercial, and industrial applications.

- Ensures smooth and reliable transport of sewage.

Conclusion

In conclusion, centrifugal pumps, agitator pumps, and grinder pumps each offer unique advantages for handling sewage and wastewater. Understanding their specific applications, features, and capabilities is crucial for selecting the right pump for a given situation. Whether it’s for high-volume fluid movement, handling abrasive slurry, or managing solid waste, these pumps play a vital role in maintaining efficient and effective waste management systems across diverse settings.

Post time: May-16-2024